Shaft Hunt

In The Beginning…There Was Wood

And hidden deep within there came forth a mighty cue shaft, capable of slaying any man, woman or beast who stood before it…Oh wait, wrong story, now where was I?

Ah yes, I remember – cold and wet from trudging around wood yards searching for ash/maple that may, just may, be good enough for cue shafts.

Initially, these boards are selected on visual appearance alone, obvious grain defects and general poor quality are identified, and a large percentage is discarded.

This takes time, a lot of time. You can’t simply call a wood supplier and ask for the ‘right’ wood. It has to be searched through, bought and paid for, cut up, checked, discarded, cut up and checked again, discarded again. This goes on until you’re left with the pieces that you hope will look good enough.

The boards are then cut lengthways to find what appears to be the straightest part of the grain. Often, they cannot be cut parallel to the board, and have to be cut at an angle across the board which, again, adds extra wastage as sometimes only one or two potential shafts can be found in a plank.

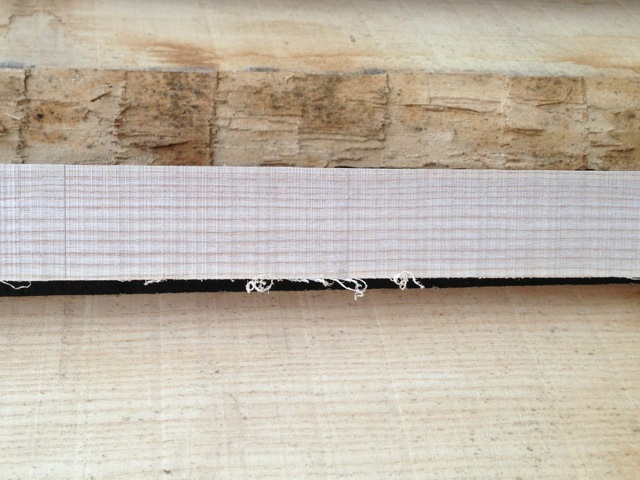

Once some reasonable looking straight grain wood has been found, and all the waste material cut out, an initial tapered cut needs to be made as we start to develop a basic cue shaft shape.

Often the wood will bend spectacularly after this cut as the inner stresses ‘relieve’ themselves and the shaft begins to move towards where ‘it wants to be’. Look how much the wood ‘springs’ apart after this tapered cut:

These bends are removed with further cuts until such time as a relatively straight and tapered over-sized square is left.

Next Step – From Square To Round…